Laser Cutting Machines Market - Global Industry, Analysis, Size, Share, Growth, Trends, and Forecasts 2024-2032

- Category: ICT, Automation and Semiconductor

- Report ID: CMR24316

- Upcoming

Laser cutting was one of the first industrial applications of lasers and one of the most widespread in the manufacturing industry since the birth of laser technology. Laser-cutting machines are sophisticated tools utilized across various industries for the precise cutting of materials such as metal, plastic, and fabric. Laser-cutting machines operate by emitting a high-powered laser beam that melts, burns, or vaporizes the material, resulting in a clean and accurate cut with minimal waste. These laser-cutting machines are prized for their versatility, capable of producing intricate designs and shapes that would be challenging or impossible to achieve with traditional cutting methods. Laser-cutting machines find applications in manufacturing, aerospace, electronics, automotive, and even in the arts and crafts sectors. With advanced technology, modern laser cutting machines feature enhanced automation, computer control, and integration with CAD software, allowing for seamless production processes and efficient material utilization.

Laser-cutting machines are highly precise tools used in various industries for cutting a wide range of materials with exceptional accuracy. They function by directing a high-powered laser beam onto the surface of the material, which melts, burns, or vaporizes it along the predetermined path. This process results in clean, sharp cuts with minimal material waste. These machines offer several advantages over traditional cutting methods, including high precision, intricate detailing, minimal material distortion, and the ability to cut complex shapes without the need for specialized tooling. Additionally, innovations such as fiber lasers have improved cutting speeds and precision, further expanding the capabilities of modern industrial tools.

Global Laser Cutting Machines Market – Competitive Landscape

On October 4, 2023, Ingersoll Rand Inc. a global provider of mission-critical flow creation and industrial solutions completed the acquisition of Oxywise s.r.o. and Fraseewoods Fabrication and Machining Ltd. On January 14, 2022, Admo Engineering made a major investment in Hugong 12m by 4.5 m 8kW fiber laser.

Key Players in the Global Laser Cutting Machines Market Include –

- Bystronic

- Mazak

- Amanda

- Prima Power

- Mitsubishi Electric

- Trotec

- Coherent

- Trumpf

- IPG Photonics

- Han’s Laser

Global Laser Cutting Machines Market – Growth Drivers

Continuous development in laser technology, including ultrafast lasers, and fiber lasers which improves cutting speed, versatility, and precision, driving the demand for laser cutting machines. Industries 4.0 technologies which include automation, and data analytics enhance efficiency, productivity, and predictive maintenance which fuel market growth. The increasing turn of industries toward automation in manufacturing for cost reduction, quality improvement, and faster production cycles boosts demand for laser cutting machines for their precision and efficiency. The need of the automotive industry for lightweight complex materials, complex designs, and efficient production processes drives the adoption of laser cutting machines for sheet metal fabrication, welding, and trimming. Laser-cutting machines are mostly important for aerospace and defense applications, including aircraft components, missile systems, and armor fabrication, fueled by increasing defense budgets and aerospace innovations. Infrastructure development, construction projects, and architectural applications require laser-cut components for precision, customization, and efficiency, contributing to market growth. The consumer electronics industry’s demand for miniaturization, complex designs, and high-precision components drives the adoption of laser-cutting machines for smartphone casing, circuit boards, and displays.

Global Laser Cutting Machines Market – Restraints

The cost of acquiring and installing laser cutting machines in industries is relatively high, posing a barrier to entry for small and medium-sized enterprises (SMEs) and limiting adoption in certain industries. Laser-cutting involves the use of high-powered laser beams, which pose safety hazards to operators if proper safety protocols are not followed, leading to concerns regarding workplace safety and regulatory compliance. Laser-cutting machines may have limitations in cutting thick materials efficiently, especially compared to traditional methods like plasma cutting or water jet cutting, restricting their application in certain industries. Reflective materials such as copper, brass, and aluminum can pose challenges for laser cutting due to their high reflectivity, requiring specialized equipment and techniques, which may limit the versatility of laser cutting machines. Laser-cutting machines emit fumes, dust, and hazardous gases during operation, necessitating compliance with environmental regulations and the implementation of proper ventilation systems, which can increase operational costs and regulatory burdens. Laser cutting machines are most effective for cutting flat or slightly curved surfaces, and they may encounter challenges when cutting complex shapes or highly curved surfaces, limiting their applicability in certain industries like automotive and aerospace. The laser-cutting machines market is highly competitive with numerous manufacturers offering similar products, leading to price competition, margin pressure, and market saturation in certain regions and industries.

Global Laser Cutting Machines Market – Opportunities

Laser-cutting machines enable intricate designs and architectural features in building construction, interior decoration, and artistic installations, fostering creativity and design innovation. Laser-cutting processes consume less energy, produce minimal waste, and enable efficient material utilization, aligning with eco-conscious industries. Laser-cutting machines find expanding applications in medical device manufacturing, precision surgical instruments, and pharmaceutical packaging, driven by stringent quality standards and technological advancements. Also increasing opportunities for laser cutting machines due to increasing industrialization, infrastructure development, and the need for advanced manufacturing technologies. Laser cutting accelerates prototyping processes, allowing for faster iterations and shorter lead times in product development cycles, benefiting industries like rapid prototyping, research, and development.

Global Laser Cutting Machines Market – Geographical Insight

The market for global laser cutting machines is segmented into regions such as North America, Latin America, Europe, Asia-Pacific, the Middle East & Africa. Asia-Pacific is the largest market for global laser-cutting machines due to the growing adoption of laser-cutting technology. China is the largest market for laser cutting machines in the Asia-Pacific region, driven by its vast manufacturing sector. In the European region, Germany leads the market for laser cutting machines, known for its precision engineering and advanced manufacturing capabilities. Countries in Europe such as Italy, Switzerland, and France also have significant contributions to the European market. In North America, the United States dominates the market for laser-cutting machines. Its focus is on innovative applications of laser cutting technology in the aerospace, defense, and healthcare sectors.

Global Laser Cutting Machines Market – Key development

- On July 18, 2023, the Metal fabrication shop added two tube laser cutting machines with one focus.

- On January 2, 2023, Gears for Africa cut lead time with investment in new Penta Bolt VII 6025 15kW fiber laser cutting machines.

- On December 23, 2022, LVD offers new cost-efficient laser cutting machines.

- On April 19, 2021, TWR Steel moves into laser fiber cutting of thin gauge.

Research Methodology: Aspects

Market research is a crucial tool for organizations aiming to navigate the dynamic landscape of customer preferences, business trends, and competitive landscapes. At Cognizance Market Research, acknowledging the importance of robust research methodologies is vital to delivering actionable insights to our clientele. The significance of such methodologies lies in their capability to offer clarity in complexity, guiding strategic management with realistic evidence rather than speculation. Our clientele seek insights that excel superficial observations, reaching deep into the details of consumer behaviours, market dynamics, and evolving opportunities. These insights serve as the basis upon which businesses craft tailored approaches, optimize product offerings, and gain a competitive edge in an ever-growing marketplace.

The frequency of information updates is a cornerstone of our commitment to providing timely, relevant, and accurate insights. Cognizance Market Research adheres to a rigorous schedule of data collection, analysis, and distribution to ensure that our reports reflect the most current market realities. This proactive approach enables our clients to stay ahead of the curve, capitalize on emerging trends, and mitigate risks associated with outdated information.

Our research process is characterized by meticulous attention to detail and methodological rigor. It begins with a comprehensive understanding of client objectives, industry dynamics, and research scope. Leveraging a combination of primary and secondary research methodologies, we gather data from diverse sources including surveys, interviews, industry reports, and proprietary databases. Rigorous data analysis techniques are then employed to derive meaningful insights, identify patterns, and uncover actionable recommendations. Throughout the process, we remain vigilant in upholding the highest standards of data integrity, ensuring that our findings are robust, reliable, and actionable.

Key phases involved in in our research process are mentioned below:

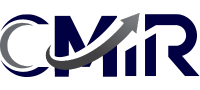

Understanding Clients’ Objectives:

Extensive Discussions and Consultations:

- We initiate in-depth discussions and consultations with our clients to gain a comprehensive understanding of their objectives. This involves actively listening to their needs, concerns, and aspirations regarding the research project.

- Through these interactions, we aim to uncover the underlying motivations driving their research requirements and the specific outcomes they hope to achieve.

Industry and Market Segment Analysis:

- We invest time and effort in comprehensively understanding our clients’ industry and market segment. This involves conducting thorough research into market trends, competitive dynamics, regulatory frameworks, and emerging opportunities or threats.

- By acquiring a deep understanding of the broader industry landscape, we can provide context-rich insights that resonate with our clients’ strategic objectives.

Target Audience Understanding:

- We analyze our clients’ target audience demographics, behaviors, preferences, and needs to align our research efforts with their consumer-centric objectives. This entails segmenting the audience based on various criteria such as age, gender, income level, geographic location, and psychographic factors.

- By understanding the nuances of the target audience, we can tailor our research methodologies to gather relevant data that illuminates consumer perceptions, attitudes, and purchase intent.

Identifying Challenges and Opportunities:

- We proactively identify the challenges and opportunities facing our clients within their respective industries. This involves conducting SWOT (Strengths, Weaknesses, Opportunities, Threats) analyses and competitive benchmarking exercises.

- By identifying potential obstacles and growth drivers, we can provide strategic recommendations that help our clients navigate complexities and capitalize on emerging opportunities effectively.

Grasping Specific Goals:

- We delve into the intricacies of our clients’ objectives to gain clarity on the specific goals they aim to accomplish through the research. This entails understanding their desired outcomes, such as market expansion, product development, or competitive analysis.

- By gaining a nuanced understanding of our clients’ goals, we can tailor our research approach to address their unique challenges and opportunities effectively.

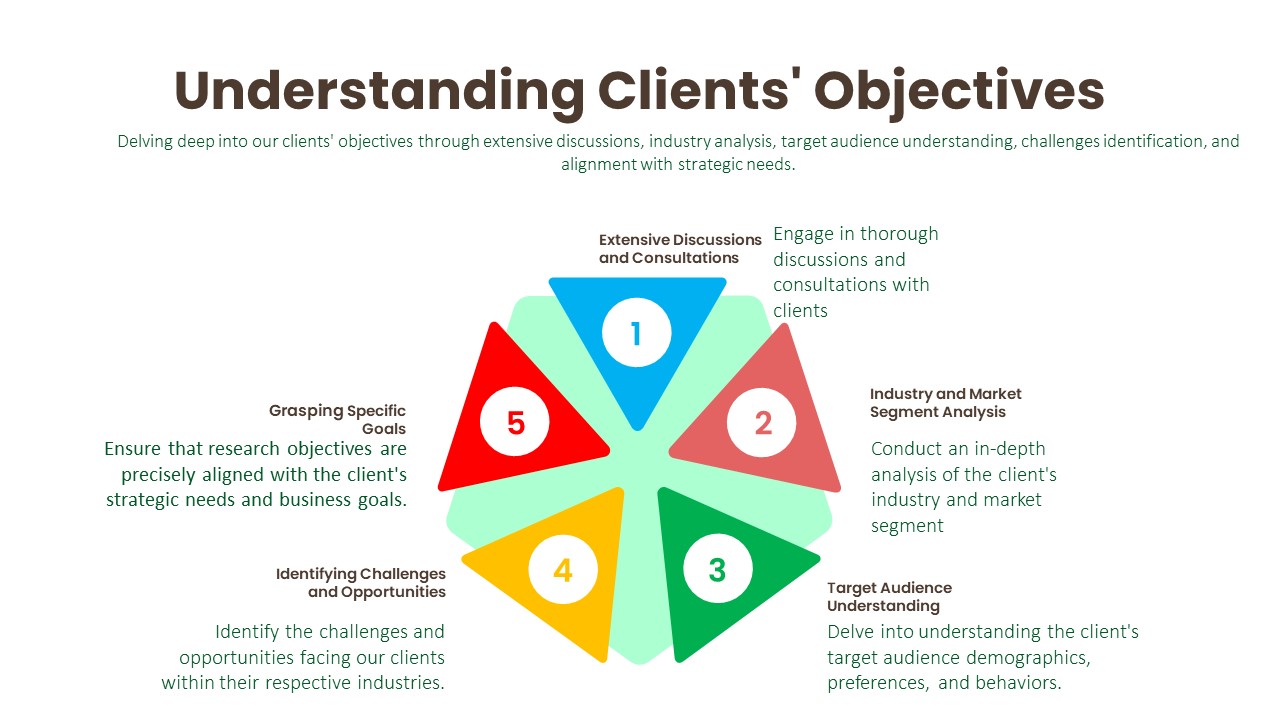

Data Collection:

Primary Research Process:

- Surveys: We design and administer surveys tailored to capture specific information relevant to our clients’ objectives. This may involve employing various survey methodologies, such as online, telephone, or face-to-face interviews, to reach target audiences effectively.

- Interviews: We conduct structured or semi-structured interviews with key stakeholders, industry experts, or target consumers to gather in-depth insights and perspectives on relevant topics. These interviews allow us to probe deeper into specific issues and uncover valuable qualitative data.

- Focus Groups: We organize focus group discussions with carefully selected participants to facilitate interactive discussions and gather collective opinions, attitudes, and preferences. This qualitative research method provides rich contextual insights into consumer behaviors and perceptions.

- Observations: We conduct observational research by directly observing consumer behaviors, interactions, and experiences in real-world settings. This method enables us to gather objective data on consumer actions and reactions without relying on self-reported information.

Secondary Research Process:

- Literature Review: We conduct comprehensive literature reviews to identify existing studies, academic articles, and industry reports relevant to the research topic. This helps us gain insights into previous research findings, theoretical frameworks, and best practices.

- Industry Reports: We analyze industry reports published by reputable trade associations (whitepapers, research studies, etc.), and government agencies (U.S. Census Bureau, Bureau of Labor Statistics, and Securities and Exchange Commission etc.) to obtain macro-level insights into market trends, competitive landscapes, and industry dynamics.

- Government Publications: We review government publications, such as economic reports, regulatory documents, and statistical databases, to gather relevant data on demographics, market size, consumer spending patterns, and regulatory frameworks.

- Online Databases: We leverage online databases, such as industry portals, and academic repositories (PubMed Central (PMC), ScienceDirect, SSRN (Social Science Research Network), Directory of Open Access Journals (DOAJ), NCBI, etc.), to access a wide range of secondary data sources, including market statistics, financial data, and industry analyses.

Data Analysis:

The data analysis phase serves as a critical juncture where raw data is transformed into actionable insights that inform strategic decision-making. Through the utilization of analytical methods such as statistical analysis and qualitative techniques like thematic coding, we uncover patterns, correlations, and trends within the data. By ensuring the integrity and validity of our findings, we strive to provide clients with accurate and reliable insights that accurately reflect the realities of the market landscape.

Transformation of Raw Data:

- Upon collecting the necessary data, we transition into the data analysis phase, where raw data is processed and transformed into actionable insights. This involves organizing, cleaning, and structuring the data to prepare it for analysis.

Utilization of Analytical Methods:

- Depending on the research objectives, we employ a diverse range of analytical methods to extract meaningful insights from the data. These methods include statistical analysis, trend analysis, regression analysis, and qualitative coding.

Statistical Analysis:

- Statistical tools are instrumental in uncovering patterns, correlations, and trends within the data. By applying statistical techniques such as descriptive statistics, hypothesis testing, and multivariate analysis, we can discern relationships and derive valuable insights.

Qualitative Analysis Techniques:

- In addition to quantitative analysis, we leverage qualitative analysis techniques to gain deeper insights from qualitative data sources such as interviews or open-ended survey responses. One such technique is thematic coding, which involves systematically categorizing and interpreting themes or patterns within qualitative data.

Integrity and Validity Maintenance:

- Throughout the analysis process, we maintain a steadfast commitment to upholding the integrity and validity of our findings. This entails rigorous adherence to established methodologies, transparency in data handling, and thorough validation of analytical outcomes.

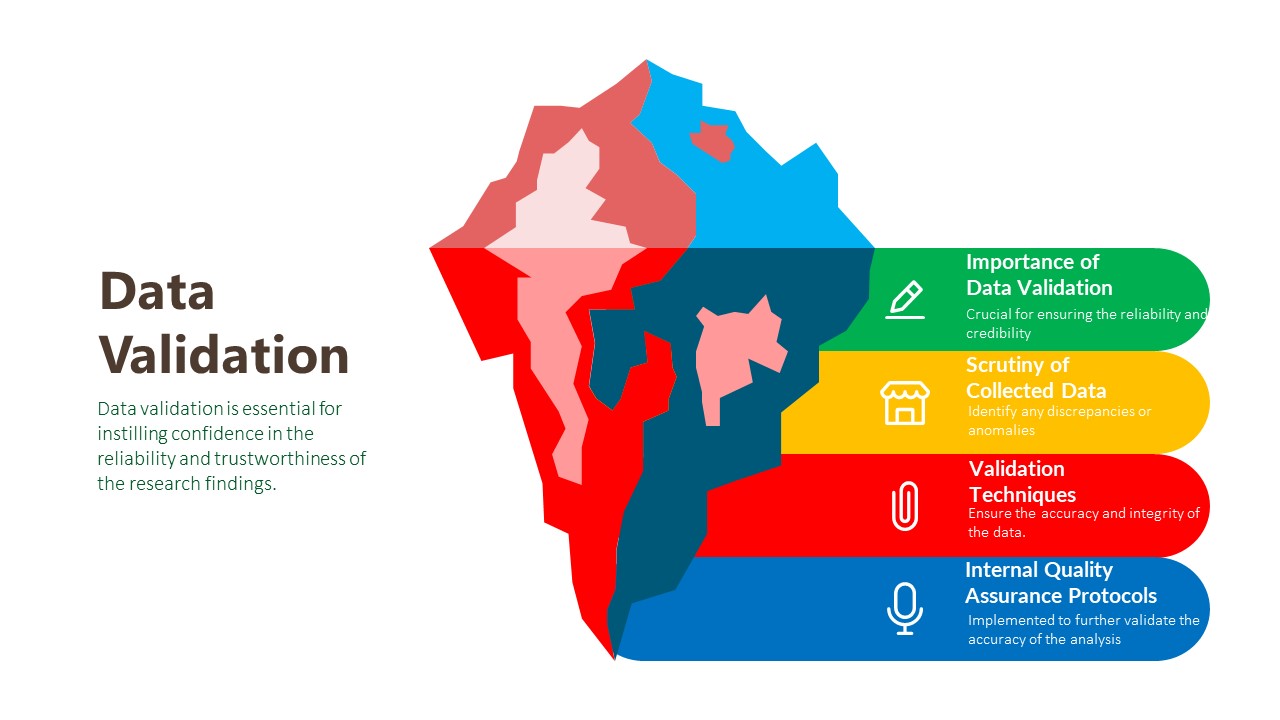

Data Validation:

The final phase of our research methodology is data validation, which is essential for ensuring the reliability and credibility of our findings. Validation involves scrutinizing the collected data to identify any inconsistencies, errors, or biases that may have crept in during the research process. We employ various validation techniques, including cross-referencing data from multiple sources, conducting validity checks on survey instruments, and seeking feedback from independent experts or peer reviewers. Additionally, we leverage internal quality assurance protocols to verify the accuracy and integrity of our analysis. By subjecting our findings to rigorous validation procedures, we instill confidence in our clients that the insights they receive are robust, reliable, and trustworthy.

Importance of Data Validation:

- Data validation is the final phase of the research methodology, crucial for ensuring the reliability and credibility of the findings. It involves a systematic process of reviewing and verifying the collected data to detect any inconsistencies, errors, or biases.

Scrutiny of Collected Data:

- The validation process begins with a thorough scrutiny of the collected data to identify any discrepancies or anomalies. This entails comparing data points, checking for outliers, and verifying the accuracy of data entries against the original sources.

Validation Techniques:

- Various validation techniques are employed to ensure the accuracy and integrity of the data. These include cross-referencing data from multiple sources to corroborate findings, conducting validity checks on survey instruments to assess the reliability of responses, and seeking feedback from independent experts or peer reviewers to validate the interpretation of results.

Internal Quality Assurance Protocols:

- In addition to external validation measures, internal quality assurance protocols are implemented to further validate the accuracy of the analysis. This may involve conducting internal audits, peer reviews, or data validation checks to ensure that the research process adheres to established standards and guidelines.

We can customize every report – free of charge – including purchasing stand-alone sections or country-level reports

We help clients to procure the report or sections of the report at their budgeted price. Kindly click on the below to avail