Failure analysis is the process of collecting and analyzing data to determine the cause of failure, often to determine corrective actions or liability. Machinery failure reveals a reaction chain of cause and effect. Usually, a deficiency is commonly referred to as the symptoms. Failure analysis can save money, lives, and resources if done correctly and acted upon. It is an important discipline in many branches of the manufacturing industry, such as the electronic industry, where it is a vital tool used in the development of new products and for the improvement of existing products. The failure analysis process relies on collecting failed components for subsequent examination of the cause or cause of failure using a wide array of methods, especially microscopy and spectroscopy. Nondestructive testing methods are valuable because the failed products are unaffected by analysis, so inspection sometimes starts using these methods. Failure analysis tools are specialized tools utilized for the diagnosis of failures in diverse materials, components, or systems. Failure analysis may use different equipment such as an optical microscope, scanning acoustic microscope, scanning electron microscope, x-ray microscope, transmission line pulse spectroscopy, dye penetrant inspection, and thermal laser stimulation.

From the beginning, failure analysis has been about finding out what went wrong in semiconductor design and manufacturing. Different approaches, tools, and equipment have improved over the decades, most recently with in-circuit monitoring, new equipment to test and inspect more circuits in parallel, and more data analysis to find patterns and improve coverage. But chipmakers and system companies now are more dependent on failure analysis for everything from digital to analog ICs and IP and they are applying it to multiple devices in a package.

Global Failure Analysis Equipment Market – Competitive Landscape

On May 11, 2023, Doppelio, a leading IoT test automation platform provider, raised USD 1.2 million in pre-series funding from Axilor Ventures & Mela Ventures. The market for global failure analysis equipment is highly competitive and continually evolving due to technological advancements and the growing demand for high-quality materials and electronics.

Some of the Key Players in the Global Failure Analysis Equipment Market Include –

Global Failure Analysis Equipment Market – Growth Driver

Increasing complexity of materials and products across various industries, necessitating advanced tools to diagnose and rectify defects and failures effectively. The semiconductors and electronics continue expansion increasing the demand for global failure analysis equipment. Market which ensures the high quality and reliability of electronic equipment. industries with stringent quality and safety requirements, such as automotive, aerospace, and healthcare rely on failure analysis equipment to meet regulatory standards and deliver safe and reliable products. The ongoing trends of miniaturization and advancements in nanotechnology further boost the demand for high-resolution analysis tools that can inspect materials and components at the nanoscale. The surge in consumer electronics and the incorporation of advanced materials and electronics in modern vehicles underscore the importance of failure analysis in addressing issues related to product safety and performance. Companies worldwide invest in infrastructure projects and place a heightened focus on product lifecycle management to extend the life and reliability of their offerings. So, the demand for the global failure analysis equipment market is on an upward trajectory.

Global Failure Analysis Equipment Market – Restraints

The cost of installing and maintaining advanced failure analysis equipment can be substantial. This initial investment can be a barrier for smaller businesses or organizations with budget constraints. Operating and interpreting results from sophisticated failure analysis equipment often requires specialized technical expertise. Companies may need to invest in training their personnel, which can be time-consuming and costly. The field of failure analysis is continually evolving, with new technologies and methods emerging regularly. This poses a challenge for businesses that must keep up with the latest tools and techniques to remain competitive. With the increasing use of digital and connected equipment, concerns regarding data security and privacy have become more significant. Protecting sensitive data obtained through failure analysis is essential. Disruption in the supply chain, as experienced during the COVID-19 pandemic, can impact the availability and delivery of critical components and equipment for failure analysis.

Global Failure Analysis Equipment Market – Opportunities

the continuous development of advanced technologies, such as higher-resolution imaging, artificial intelligence, and machine learning, provides opportunities for innovation in failure analysis equipment, allowing for more accurate and efficient analysis. The expanding semiconductor industry, driven by the demand for electronics and technological advancements, presents a significant opportunity for the failure analysis equipment market. The need for precise analysis tools to ensure high-quality semiconductor components is on the rise. Increased investments in research and development across various industries necessitate advanced failure analysis equipment for materials characterization and component analysis, fostering global failure analysis equipment market growth.

Global Failure Analysis Equipment Market – Geographical Insight

The market for global failure analysis equipment is segmented into regions such as North America, Latin America, Asia-Pacific, the Middle East & Africa. North America is the largest region due to benefits from a strong presence of high-tech industries, including semiconductors and electronics. The continuous demand for advanced analysis tools in these industries drives the failure analysis equipment’s market growth. The United States is a significant player in the global failure analysis equipment market. The Asia-Pacific region is a growing region due to the forefront of semiconductor manufacturing, and electronics production. The countries from Asia-Pacific regions such as China, Japan, South Korea, and Taiwan play a pivotal role in the global failure analysis equipment market. Europe also has a substantial presence in the failure analysis equipment market, with countries like Germany, the United Kingdom, and France leading in manufacturing and research.

Global Failure Analysis Equipment Market – Key Development

Research Methodology: Aspects

Market research is a crucial tool for organizations aiming to navigate the dynamic landscape of customer preferences, business trends, and competitive landscapes. At Cognizance Market Research, acknowledging the importance of robust research methodologies is vital to delivering actionable insights to our clientele. The significance of such methodologies lies in their capability to offer clarity in complexity, guiding strategic management with realistic evidence rather than speculation. Our clientele seek insights that excel superficial observations, reaching deep into the details of consumer behaviours, market dynamics, and evolving opportunities. These insights serve as the basis upon which businesses craft tailored approaches, optimize product offerings, and gain a competitive edge in an ever-growing marketplace.

The frequency of information updates is a cornerstone of our commitment to providing timely, relevant, and accurate insights. Cognizance Market Research adheres to a rigorous schedule of data collection, analysis, and distribution to ensure that our reports reflect the most current market realities. This proactive approach enables our clients to stay ahead of the curve, capitalize on emerging trends, and mitigate risks associated with outdated information.

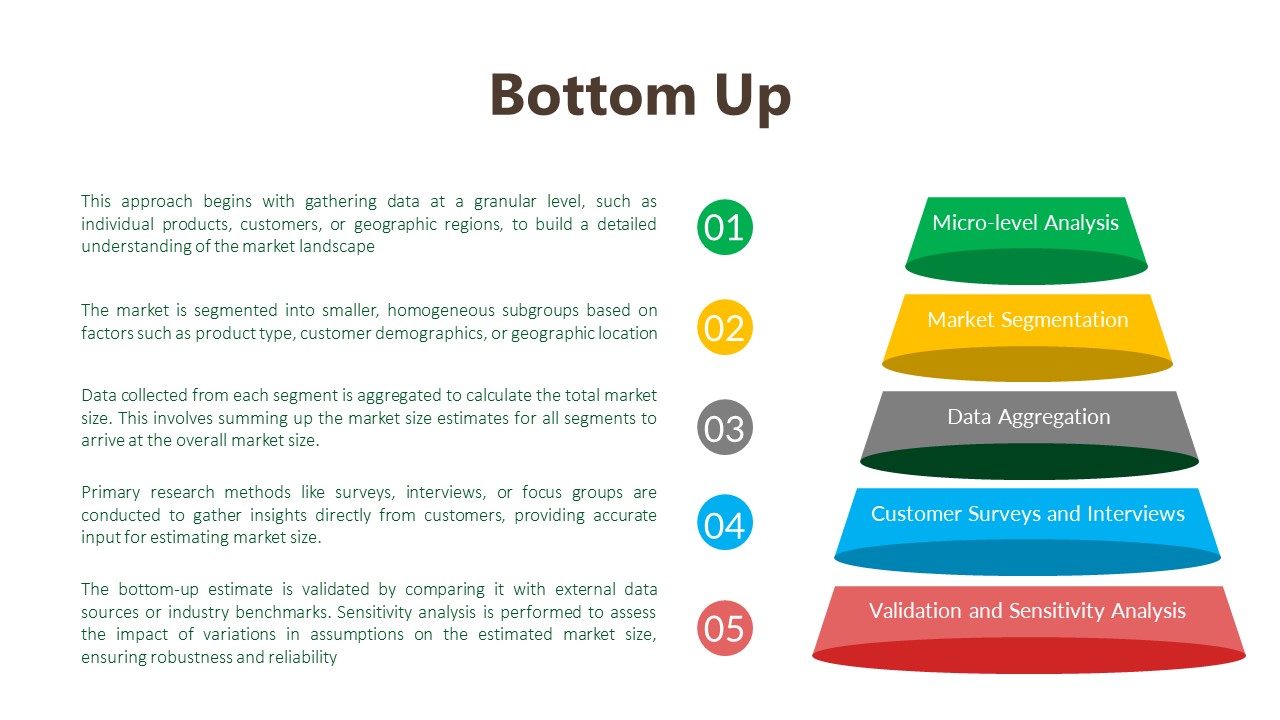

Our research process is characterized by meticulous attention to detail and methodological rigor. It begins with a comprehensive understanding of client objectives, industry dynamics, and research scope. Leveraging a combination of primary and secondary research methodologies, we gather data from diverse sources including surveys, interviews, industry reports, and proprietary databases. Rigorous data analysis techniques are then employed to derive meaningful insights, identify patterns, and uncover actionable recommendations. Throughout the process, we remain vigilant in upholding the highest standards of data integrity, ensuring that our findings are robust, reliable, and actionable.

Key phases involved in in our research process are mentioned below:

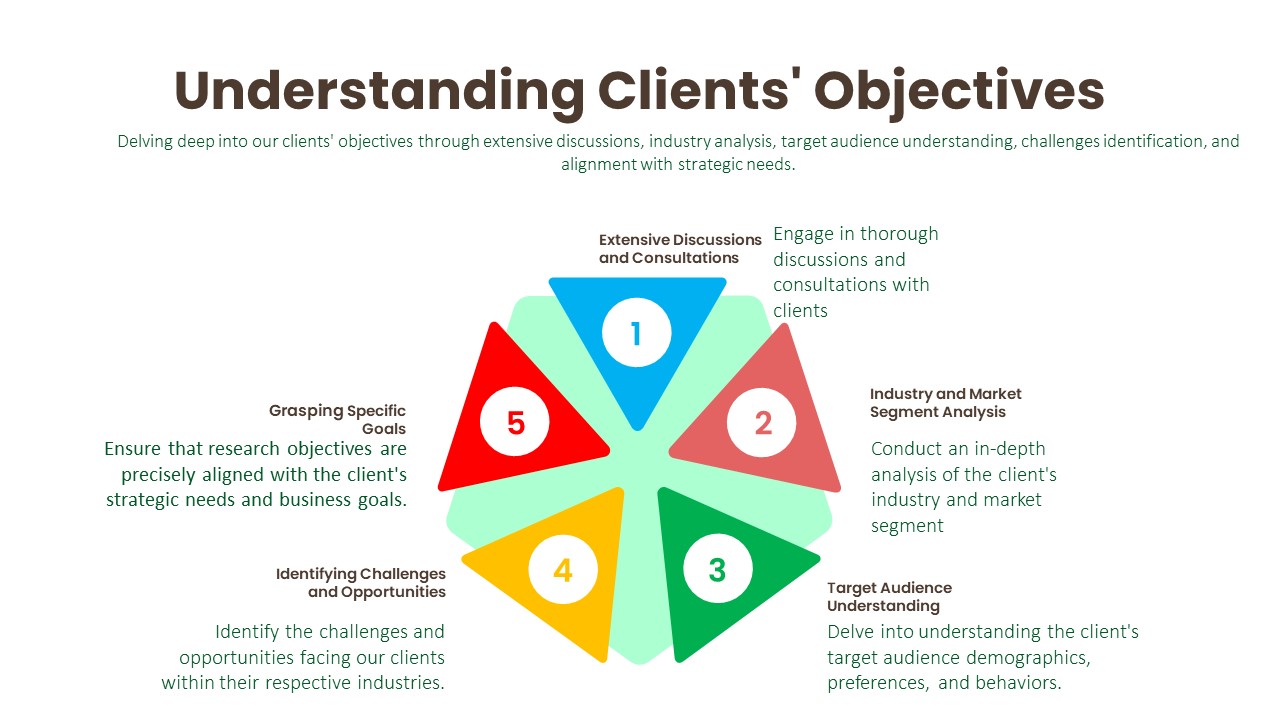

Understanding Clients’ Objectives:

Extensive Discussions and Consultations:

Industry and Market Segment Analysis:

Target Audience Understanding:

Identifying Challenges and Opportunities:

Grasping Specific Goals:

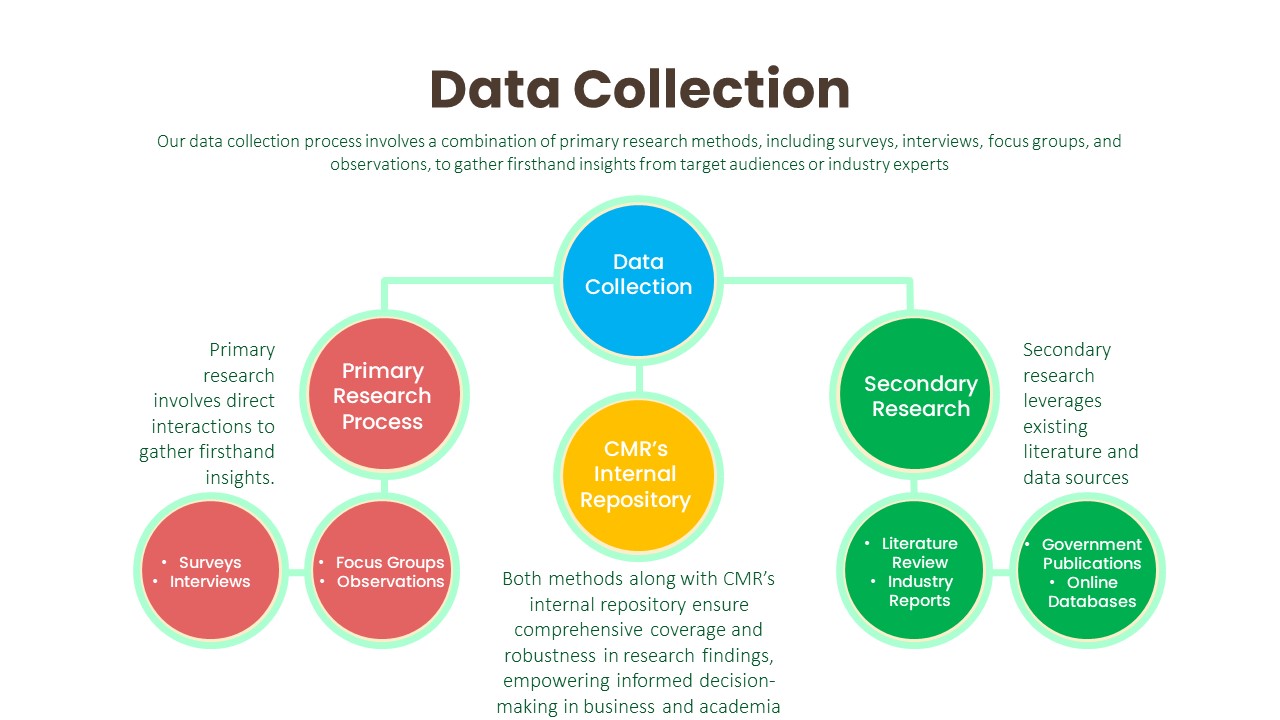

Data Collection:

Primary Research Process:

Secondary Research Process:

Data Analysis:

The data analysis phase serves as a critical juncture where raw data is transformed into actionable insights that inform strategic decision-making. Through the utilization of analytical methods such as statistical analysis and qualitative techniques like thematic coding, we uncover patterns, correlations, and trends within the data. By ensuring the integrity and validity of our findings, we strive to provide clients with accurate and reliable insights that accurately reflect the realities of the market landscape.

Transformation of Raw Data:

Utilization of Analytical Methods:

Statistical Analysis:

Qualitative Analysis Techniques:

Integrity and Validity Maintenance:

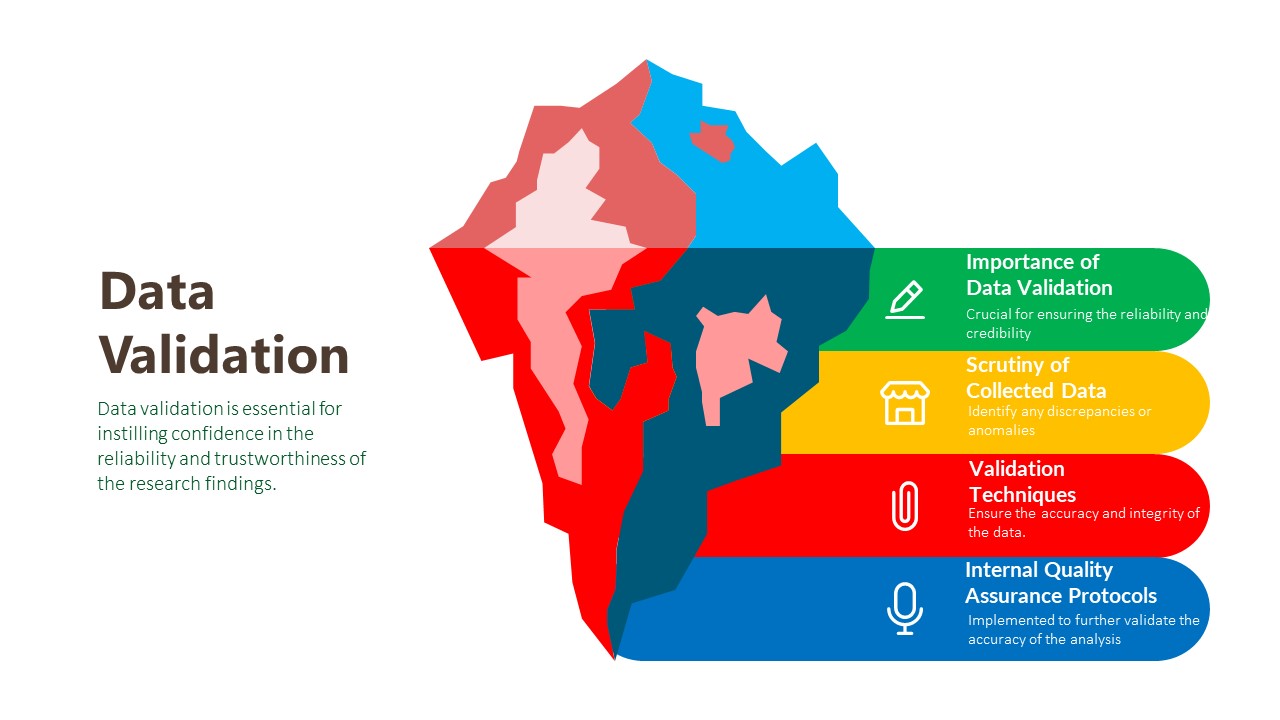

Data Validation:

The final phase of our research methodology is data validation, which is essential for ensuring the reliability and credibility of our findings. Validation involves scrutinizing the collected data to identify any inconsistencies, errors, or biases that may have crept in during the research process. We employ various validation techniques, including cross-referencing data from multiple sources, conducting validity checks on survey instruments, and seeking feedback from independent experts or peer reviewers. Additionally, we leverage internal quality assurance protocols to verify the accuracy and integrity of our analysis. By subjecting our findings to rigorous validation procedures, we instill confidence in our clients that the insights they receive are robust, reliable, and trustworthy.

Importance of Data Validation:

Scrutiny of Collected Data:

Validation Techniques:

Internal Quality Assurance Protocols:

We can customize every report – free of charge – including purchasing stand-alone sections or country-level reports

We help clients to procure the report or sections of the report at their budgeted price. Kindly click on the below to avail

Cognizance market research is continuously guiding customers around the globe towards strategies for transformational growth. Today, businesses have to innovate more than ever before, not just to survive, but to succeed in the future

© 2023 All rights Reserved. Cognizance Market Research