A prominent research firm, Cognizance Market Research added a cutting-edge industry report on “Global Vibrating Ring Mills for Mineral Market”. The report studies the current and past growth trends and opportunities for the market to gain valuable insights during the forecast period from 2023 to 2030.

Global Vibrating Ring Mills for Mineral Market Analysis:

According to cognizance market research, the Global Vibrating Ring Mills for Mineral Market was valued at US$ 55.58 Million in 2022 and is anticipated to reach US$ 80.19 Million by the end of 2030 with a CAGR of 5.01% from 2023 to 2030.

What is the Global Vibrating Ring Mills for Mineral Market?

Vibrating ring mills for minerals are specialized equipment used in mineral processing and sample preparation. These mills employ a unique mechanism involving a vibrating disc or ring that imparts rapid oscillations to the grinding vessels, facilitating efficient comminution of mineral samples. The vibrating motion enhances the grinding process by promoting particle breakage and reducing the particle size of the material.

The increasing demand for efficient mineral processing solutions is a primary driver for the growth of the vibrating ring mills market. Technological advancements in these mills, enhancing their precision and capabilities, contribute significantly to market expansion. Growing awareness of the importance of accurate mineral analysis for sustainable mining practices fuels market growth.

Ongoing technological innovations, such as the integration of artificial intelligence and automation, are shaping the evolution of vibrating ring mills, leading to more efficient and user-friendly solutions. vibrating ring mills find applications in geological and metallurgical research, mineral exploration, and the mining industry for sample preparation and accurate mineral composition analysis.

Stringent environmental regulations are influencing the market, driving the adoption of eco-friendly and sustainable mineral processing technologies, where vibrating ring mills play a role. The market is characterized by moderate consolidation, with key players engaging in mergers, acquisitions, and strategic alliances to enhance their product portfolios and global market presence. The global vibrating ring mills for the mineral market are expected to witness sustained growth, propelled by continual advancements in technology, increased mineral exploration activities, and a focus on sustainable mining practices.

Global Vibrating Ring Mills for Mineral Market Outlook:

The global vibrating ring mills for the mineral market are poised for continued growth driven by increasing demand for efficient mineral processing solutions across various industries. Ongoing advancements in vibrating ring mill technologies, including automation, real-time monitoring, and enhanced precision, are anticipated to shape the market landscape, offering more sophisticated and user-friendly solutions.

The surge in mineral exploration activities globally, driven by the demand for raw materials, will contribute to sustained market expansion for vibrating ring mills used in sample preparation and mineral analysis. Stringent environmental regulations are influencing product development, with a growing emphasis on eco-friendly and sustainable features in vibrating ring mills, aligning with the broader industry’s commitment to responsible mining practices.

A notable trend is the increasing demand for customized vibrating ring mills tailored to specific client requirements, reflecting a shift towards more personalized solutions to meet diverse industry needs. The market may witness further consolidation as key players engage in strategic mergers, acquisitions, and partnerships to strengthen their market position, expand product portfolios, and enhance global reach.

Increased investment in research and development initiatives by key market players will drive innovation, leading to the introduction of more advanced vibrating ring mills with improved functionalities. The integration of industry 4.0 technologies, such as IoT and data analytics, into vibrating ring mills, is anticipated to enhance overall efficiency, facilitate predictive maintenance, and further streamline the mineral processing workflow.

Geographically, North America is expected to experience sustained growth in the vibrating ring mills for the mineral market, driven by the robust mining industry and ongoing mineral exploration activities. The prominence of the mining industry in North America, particularly in countries like the United States and Canada, will be a significant factor propelling the demand for vibrating ring mills for efficient mineral processing.

Global economic trends and fluctuations may influence investment in mineral exploration and mining activities, subsequently impacting the demand for vibrating ring mills. Challenges related to high initial costs and the need for specialized technical expertise for operating advanced vibrating ring mills may pose hurdles to widespread adoption, impacting market growth.

Segment Analysis:

Suited for users requiring hands-on control, manual vibrating ring mills offer precision in sample preparation, allowing operators to adjust parameters based on specific mineral processing needs. Featuring automation and advanced control systems, automatic vibrating ring mills streamline the grinding process, enhancing efficiency and reducing the need for constant manual intervention. Combining aspects of both manual and automatic mills, semi-automatic vibrating ring mills provide a balance between user control and automated functionalities, catering to diverse user preferences.

Manufacturers engage directly with end-users, mining companies, and research institutions. Direct sales channels allow for personalized interactions, customization, and direct feedback. Collaborating with distributors and resellers expands market reach, leveraging the local expertise of intermediaries to mills to a broader audience. The increasing prevalence of online sales platforms facilitates global accessibility, providing convenience for buyers and allowing manufacturers to reach a diverse customer base.

Geographical Analysis:

North America holds a prominent position in the global vibrating ring mills market, driven by a robust mining sector and a high demand for efficient mineral processing equipment. The region is at the forefront of technological advancements, contributing to the development of sophisticated vibrating ring mills with advanced features for precise mineral analysis. Stringent environmental regulations in North America drive the adoption of eco-friendly vibrating ring mills, aligning with the region’s commitment to sustainable mining practices.

Meanwhile, the Asia-Pacific region, experiencing rapid industrialization, drives the demand for mineral resources, fostering the adoption of vibrating ring mills in mining and material processing. Emerging markets in countries like China and India present significant growth opportunities, with increased mineral exploration activities fueling the market for vibrating ring mills. European countries are known for their technological excellence, reflected in the design and manufacturing of high-precision vibrating ring mills suitable for intricate mineral analysis.

Latin America, rich in mineral resources, sustains a steady demand for vibrating ring mills in mining operations, exploration, and geological research. The Middle East and Africa witness a growing mining sector, driving the need for efficient mineral processing equipment, including vibrating ring mills. Increasing infrastructure development projects in the region lead to heightened demand for minerals, further supporting the market for vibrating ring mills.

The report offers the revenue of the Global Vibrating Ring Mills for Mineral Market for the period 2020-2030, considering 2020 & 2021 as a historical year, 2022 as the base year, and 2023 to 2030 as the forecast year. The report also provides the compound annual growth rate (CAGR) for the global vibrating ring mills for the mineral market for the forecast period. The global vibrating ring mills for mineral market report provides insights and in-depth analysis into developments impacting enterprises and businesses on a regional and global level. The report covers the global vibrating ring mills for mineral market performance in terms of revenue contribution from several segments and comprises a detailed analysis of key drivers, trends, restraints, and opportunities prompting revenue growth of the global vibrating ring mills for mineral market.

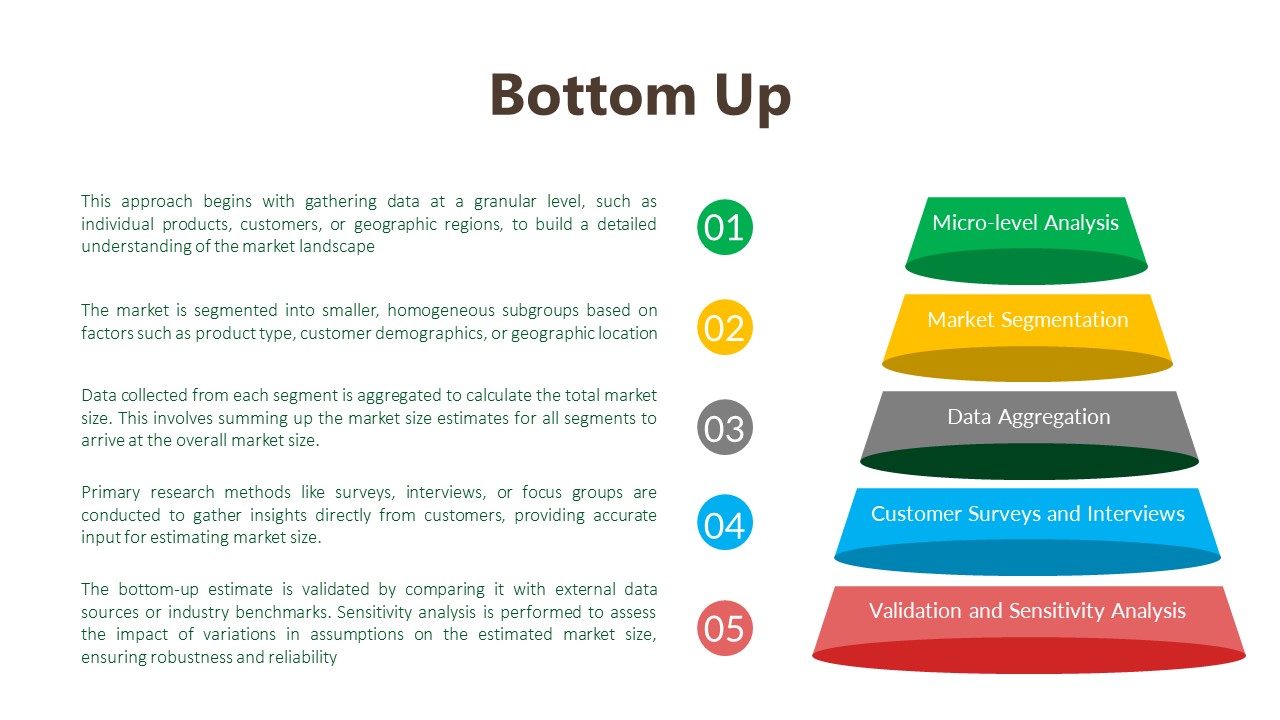

The report has been prepared after wide-ranging secondary and primary research. Secondary research included internet sources, numerical data from government organizations, trade associations, and websites. Analysts have also employed an amalgamation of bottom-up and top-down approaches to study numerous phenomena in the global vibrating ring mills for the mineral market. Secondary research involved a detailed analysis of significant players’ product portfolios. Literature reviews, press releases, annual reports, white papers, and relevant documents have been also studied to understand the global vibrating ring mills for the mineral market. Primary research involved a great extent of research efforts, wherein experts carried out interviews telephonic as well as questioner-based with industry experts and opinion-makers.

The report includes an executive summary, along with a growth pattern of different segments included in the scope of the study. The Y-o-Y analysis with elaborate market insights has been provided in the report to comprehend the Y-o-Y trends in the global vibrating ring mills for the mineral market. Additionally, the report focuses on altering competitive dynamics in the global market. These indices serve as valued tools for present market players as well as for companies interested in participating in the global vibrating ring mills for the mineral market. The subsequent section of the global vibrating ring mills for mineral market report highlights the USPs, which include key industry events (product launch, research partnership, acquisition, etc.), technology advancements, pipeline analysis, prevalence data, and regulatory scenarios.

Global Vibrating Ring Mills for Mineral Market Competitive Landscape:

There are several small and major firms participating in the highly fragmented Global Vibrating Ring Mills for Mineral Market. The new strategies formed by companies revolve around accuracy and precision. The following are some of the major market participants:

The report explores the competitive scenario of the Global Vibrating Ring Mills for Mineral Market. Major players working in the Global Vibrating Ring Mills for the Mineral Market have been named and profiled for unique commercial attributes. Company overview (company description, product portfolio, geographic presence, employee strength, Key management, etc.), financials, SWOT analysis, recent developments, and key strategies are some of the features of companies profiled in the Global Vibrating Ring Mills for Mineral Market report.

Segmentation:

Global Vibrating Ring Mills for Mineral Market, By Product Type:

Global Vibrating Ring Mills for Mineral Market, By Distribution Channel:

Global Vibrating Ring Mills for Mineral Market, by Region:

Research Methodology: Aspects

Market research is a crucial tool for organizations aiming to navigate the dynamic landscape of customer preferences, business trends, and competitive landscapes. At Cognizance Market Research, acknowledging the importance of robust research methodologies is vital to delivering actionable insights to our clientele. The significance of such methodologies lies in their capability to offer clarity in complexity, guiding strategic management with realistic evidence rather than speculation. Our clientele seek insights that excel superficial observations, reaching deep into the details of consumer behaviours, market dynamics, and evolving opportunities. These insights serve as the basis upon which businesses craft tailored approaches, optimize product offerings, and gain a competitive edge in an ever-growing marketplace.

The frequency of information updates is a cornerstone of our commitment to providing timely, relevant, and accurate insights. Cognizance Market Research adheres to a rigorous schedule of data collection, analysis, and distribution to ensure that our reports reflect the most current market realities. This proactive approach enables our clients to stay ahead of the curve, capitalize on emerging trends, and mitigate risks associated with outdated information.

Our research process is characterized by meticulous attention to detail and methodological rigor. It begins with a comprehensive understanding of client objectives, industry dynamics, and research scope. Leveraging a combination of primary and secondary research methodologies, we gather data from diverse sources including surveys, interviews, industry reports, and proprietary databases. Rigorous data analysis techniques are then employed to derive meaningful insights, identify patterns, and uncover actionable recommendations. Throughout the process, we remain vigilant in upholding the highest standards of data integrity, ensuring that our findings are robust, reliable, and actionable.

Key phases involved in in our research process are mentioned below:

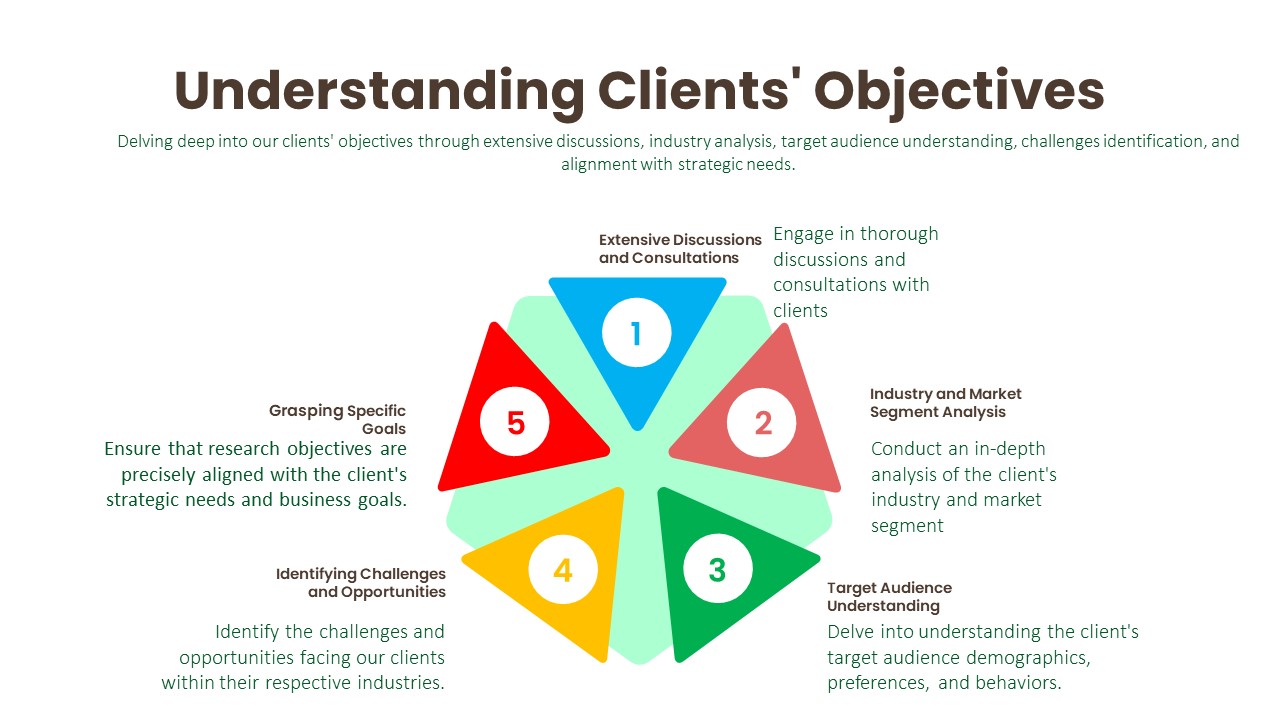

Understanding Clients’ Objectives:

Extensive Discussions and Consultations:

Industry and Market Segment Analysis:

Target Audience Understanding:

Identifying Challenges and Opportunities:

Grasping Specific Goals:

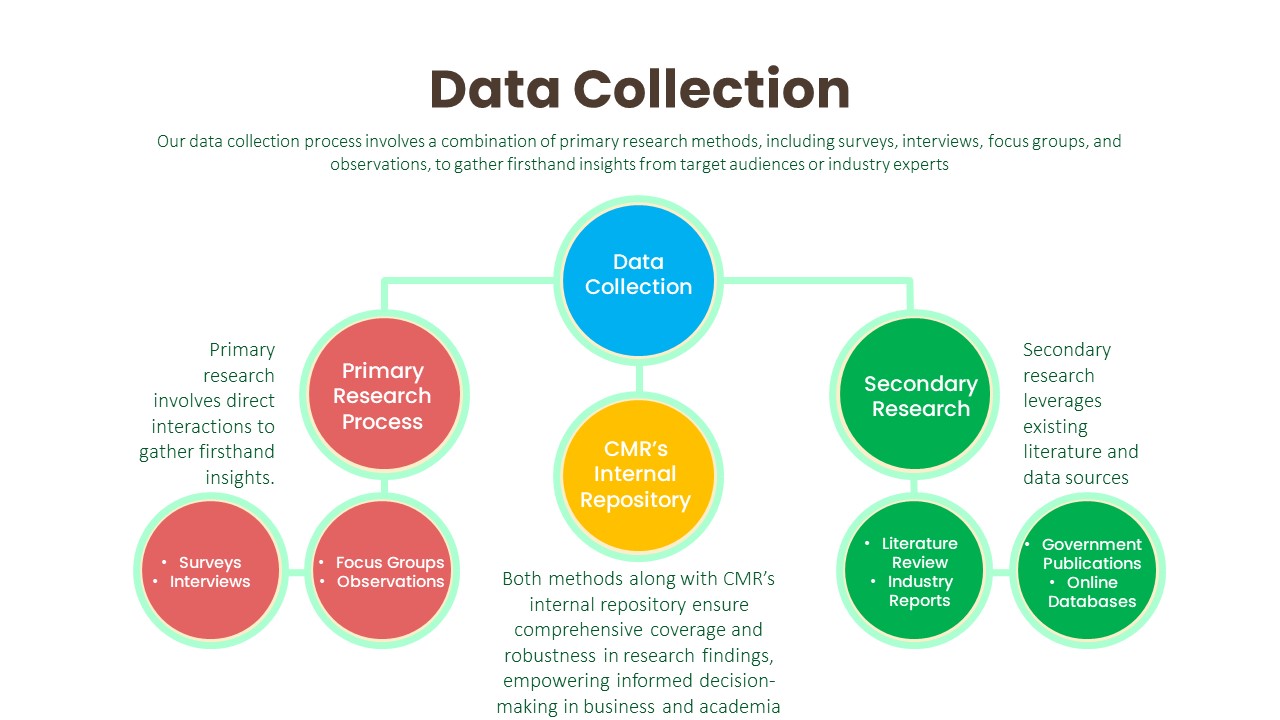

Data Collection:

Primary Research Process:

Secondary Research Process:

Data Analysis:

The data analysis phase serves as a critical juncture where raw data is transformed into actionable insights that inform strategic decision-making. Through the utilization of analytical methods such as statistical analysis and qualitative techniques like thematic coding, we uncover patterns, correlations, and trends within the data. By ensuring the integrity and validity of our findings, we strive to provide clients with accurate and reliable insights that accurately reflect the realities of the market landscape.

Transformation of Raw Data:

Utilization of Analytical Methods:

Statistical Analysis:

Qualitative Analysis Techniques:

Integrity and Validity Maintenance:

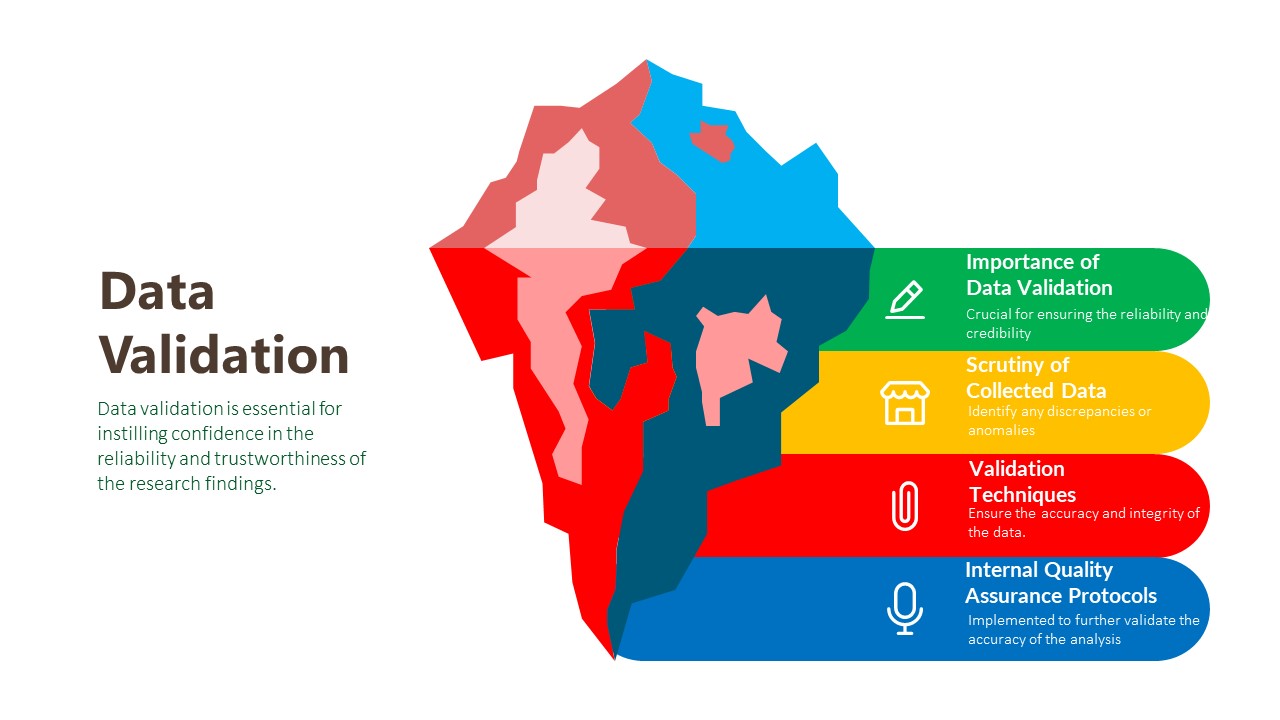

Data Validation:

The final phase of our research methodology is data validation, which is essential for ensuring the reliability and credibility of our findings. Validation involves scrutinizing the collected data to identify any inconsistencies, errors, or biases that may have crept in during the research process. We employ various validation techniques, including cross-referencing data from multiple sources, conducting validity checks on survey instruments, and seeking feedback from independent experts or peer reviewers. Additionally, we leverage internal quality assurance protocols to verify the accuracy and integrity of our analysis. By subjecting our findings to rigorous validation procedures, we instill confidence in our clients that the insights they receive are robust, reliable, and trustworthy.

Importance of Data Validation:

Scrutiny of Collected Data:

Validation Techniques:

Internal Quality Assurance Protocols:

Report Scope:

Attribute

Description

Market Size

US$ 80.19 Million (2030)

Compound Annual Growth Rate (CAGR)

5.01%

Base Year

2022

Forecast Period

2023-2030

Forecast Units

Value (US$ Million)

Report Coverage

Revenue Forecast, Competitive Landscape, Growth Factors, and Trends

Geographies Covered

North America, Europe, Asia Pacific, Latin America, Middle East & Africa

Countries Covered

U.S., Canada, Germany, U.K., France, Spain, Italy, Rest of Europe, Japan, China, India, Australia & New Zealand, South Korea, Rest of Asia Pacific, Brazil, Mexico, Rest of Latin America, GCC, South Africa, Rest of Middle East & Africa

Key Companies Profiled

Fritsch GmbH, Rocklabs Ltd., Essa Australia Limited, Herzog Machinenfabrik GmbH & Co. KG., Metso Outotec Corporation, Retsch GmbH, Glen Mills Inc, XRF Scientific Limited, Makvern Panalytical, Sepro Mineral Systems Corp., Spex SamplePrep, MTI Corporation, IMP Automation Canada Ltd, Qiagen, Buehler.

It was Valued at US$ 55.58 million in 2022.

It is projected to reach more than US$ 80.19 Million by 2030.

It is anticipated to be 5.01% from 2023 to 2030.

Trend: the adoption of industry 4.0 trends, including IoT and data analytics, in vibrating ring mills for minerals, enhances operational efficiency, facilitates predictive maintenance, and provides real-time insights.

Driver: Growing demand for mineral fuels exploration activities, driving the need for efficient vibrating ring mills in sample preparation and mineral analysis processes.

Opportunities: The burgeoning industrialization and mineral exploration in Asia-Pacific present lucrative opportunities for market growth, creating a demand for advanced vibrating ring mills.

Challenges: The substantial initial investment required for advanced vibrating ring mills poses a challenge, particularly for small and medium-sized enterprises, impacting adoption rates.

Fritsch GmbH, Rocklabs Ltd., Essa Australia Limited, Herzog Machinenfabrik GmbH & Co. KG., Metso Outotec Corporation, Retsch GmbH, Glen Mills Inc, XRF Scientific Limited, Makvern Panalytical, Sepro Mineral Systems Corp., Spex SamplePrep, MTI Corporation, IMP Automation Canada Ltd, Qiagen, Buehler.

We can customize every report – free of charge – including purchasing stand-alone sections or country-level reports

We help clients to procure the report or sections of the report at their budgeted price. Kindly click on the below to avail

Cognizance market research is continuously guiding customers around the globe towards strategies for transformational growth. Today, businesses have to innovate more than ever before, not just to survive, but to succeed in the future

© 2023 All rights Reserved. Cognizance Market Research