The thermoformed shallow trays market around the world is concerned with the manufacturing and application of thin and lightweight yet sturdy trays made through the thermoforming process. These trays are used for storage, presentation, and protection of various forms of products in the food and beverages sector, pharma, electronics, and consumer products segment. The shallow formation makes them stack and store easily thus serving the business needs of retail and transportation.

Shallow thermoformed trays employ substrates such as PET, PP, PVC, and polystyrene because of their flexibility, low cost, and reusability. The need for these trays is today increasing more and more as people look forward to an ecological and attractive packaging solution, especially in the food industry where they are mostly used for fruits and vegetables, baked products, and ready-to-eat foods, etc.

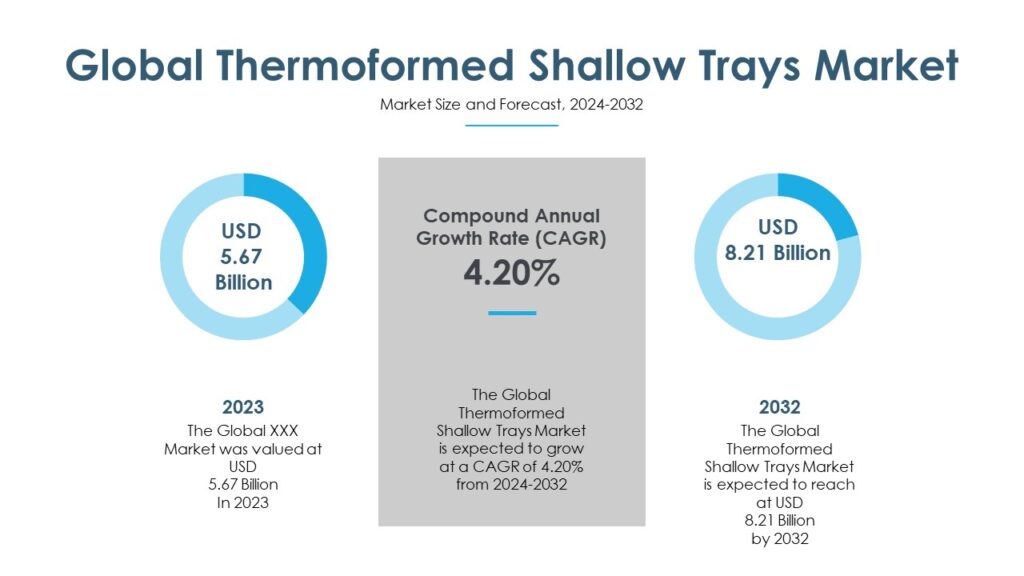

The global thermoformed shallow trays market was valued at US$ 5.67 Billion in 2023 and is anticipated to reach US$ 8.21 Billion by the end of 2030 with a CAGR of 4.2% from 2024 to 2032.

The global thermoformed shallow trays market was valued at US$ 5.67 Billion in 2023 and is anticipated to reach US$ 8.21 Billion by the end of 2030 with a CAGR of 4.2% from 2024 to 2032.

In heavens of continually rising awareness about sustainable products, manufacturers are trying to produce biodegradable and compostable materials to meet the new standards set by the regulatory bodies as well as the preferences of customers. This growth in the market is due to featuring technologies that allow increased rates of thermoforming, and improved accuracy in the designs as well as lower volumes of material left out in the process.

Factors Driving the Growth of the Global Thermoformed Shallow Trays Market in North America:

The growth of the North American thermoformed shallow tray market is explained by factors such as the food and beverage sector being strong in the region, and the growing need for packaging materials, particularly convenience packaging, is another reason. As consumers shift to consume more ready-to-eat foods, packaged snacks, fresh fruits and vegetables packaging and reusable trays have become more crucial.

The focus on reducing plastic material usage and environmental sustainability is forcing manufacturers to form new sustainable packaging solutions such as recirculation and biodegradable materials. With the growing awareness of environmental degradation, firms in North America are shifting towards the manufacture of shallow trays that are environmentally friendly thus propelling the market growth.

Furthermore, technology in thermoforming is enhancing the quality and increasing the efficiency of the products in the market thus the expansion. New process technologies like recyclable polymers are fulfilling both utility and sustainability needs, and are also boosting demand.

Based on the new sources of packaging demand, the emergence of e-commerce and the delivery of food online has emerged as a new source of packaging demand. These sectors readily adopt thermoformed shallow trays for product-safe carriage and storage, thus accelerating industry growth.

Finally, the legislation that enforces plastic consumption and environmentally friendly policies is creating an interest in thermoformed trays in North America and boosting the total market scenery.

Competitive Insights:

Some of the key players of the global thermoformed shallow tray market are as follows: Amcor Plc, DS Smith Plc, Sonoco Products Company, Winpak Ltd, Royal Interpack Group, Tekni-Plex LLC, Universal Protective Packaging Inc., Andex, Sinclair & Rush Inc., Faerch A/S, Easypack LLC.

The thermoformed shallow trays industry is quite fragmented and major manufacturers are emphasized on quality, sustainability innovation, and new markets. Current leaders in the market with broad portfolios and efforts toward more environment-friendly offerings, fitting the growing consumer attention to the subject, are Sonoco Products Company, Berry Global Inc., and Amcor plc.

Sustainability is now an important competitive edge and players are incorporating recyclable, biodegradable, and compostable items into the market. This helps address environmental issues and is in line with set regulations in North America and Europe and thus, an edge to these companies to capture the conscience consumer.

It’s about innovations in thermoforming technology, for example, precision molding, and a decrease of material losses. Industry giants such as Placon Corporation, and Greiner Packaging use sophisticated technologies to develop standard and specialized shallow trays that are cheaper but meet certain market standards hence improving their positioning in the market.

Another strategy is customization as well as design differentiation where different organizations provide structures for packaging and or labeling that fit all the various industries including foods and beverages, drugs, and electronics. With this strategy, players can develop select markets with focused solutions in turn enhancing customer bonds.

Market incumbents actively implement the strategies of geographic expansion as well as partnerships. That is why creating regional manufacturing sites and cooperating with distributors allow companies to expand into new geographical areas, including the Asia-Pacific region while maintaining their leadership in North America or Europe. All these approaches help create long-term growth and competitiveness in the global thermoformed shallow trays market.